Ningbo Hexin Engineering Technology Co., Ltd. specializes in providing customers with innovative solutions through high-precision mapping and reverse design technology. Relying on advanced mapping equipment and professional software, the company accurately collects spatial data of objects and builds digital models to realize efficient reverse design in the fields of machinery manufacturing, industrial design, and building renovation. The team restores the details of product structure through refined mapping, optimizes the prototype with forward design thinking, helps customers to complete product iteration, process upgrading and technological transformation, and successfully delivers a number of complex projects in the scenarios of equipment manufacturing, cultural relics preservation, mold development, etc., which helps enterprises to reduce costs and increase efficiency with data-driven design.

Product Reverse Design

The reverse design process of Ningbo Hexin Engineering Technology Co., Ltd. is based on high-precision 3D laser scanning and drone mapping technology, and through the five core steps of [data acquisition - 3D scanning and modeling - feature analysis - CAD model reconstruction - prototype optimization], we can accurately restore the digital models of complex parts, industrial equipment and architectural structures, and optimize the performance of the products and production processes by combining with the forward design thinking to provide mass-producible technical solutions in the fields of machinery manufacturing, mold development and product comparison. It provides mass-producible technical solutions in the fields of mechanical manufacturing, mold development, product comparison, etc., and helps enterprises shorten the R&D cycle, reduce transformation costs and enhance market competitiveness with data-driven reverse engineering.

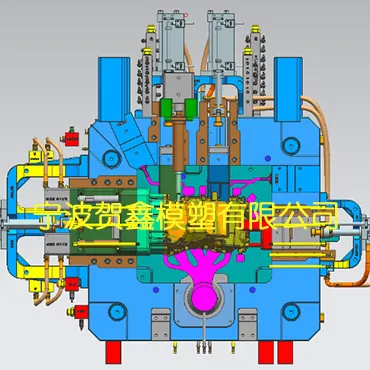

3D mold design uses digital technology to accurately build mold structure, covering die casting, low pressure and gravity casting three major processes, helping enterprises to efficiently produce high-precision parts. Die casting mold design is good at manufacturing complex parts (such as auto parts, electronic shell), relying on high-pressure high-speed filling technology, to ensure that thin-walled parts of the surface finish and dimensional precision, the core focus on the mold pressure strength and cooling efficiency; low-pressure mold design to fill the cavity with smooth low-pressure (0.01-0.05MPa) to reduce the defects of the air holes, adaptable to the aluminum alloy wheels and other high requirements of the densification of the large and medium-sized products, focusing on Optimization of pouring system and shrinkage channel; gravity mold design by virtue of the natural molding of metal weight, low cost, short cycle time, suitable for pipeline joints and other simple structure of the mass production, need to be targeted to solve the problem of insufficient filling and shrinkage. All three types of processes can be used to pre-judge defects through 3D modeling and simulation analysis (e.g., melt flow simulation, thermal stress detection), optimize parting surfaces and exhaust design, and reduce molding costs while improving yields, so as to meet the diversified demands for precision castings in automotive, aerospace, and home appliance industries.

Die Casting Mold Design

Hersin uses advanced CAD/CAM software (e.g. SolidWorks, AutoCAD) to achieve high-precision digital development of molds and optimize runner systems, cooling structures and ejection solutions to improve mold life and productivity. Our design services cover automotive parts, electronic parts, household appliances and other die casting areas, through 3D simulation verification to reduce the cost of trial mold, to ensure the accuracy of the parting surface and tolerance ± 0.01mm control, to support the design of complex curved surfaces and thin-walled structures, to help companies to shorten the development cycle of 30% products. Provide customized mold frame, slide and exhaust system solutions, in line with ISO9001 standards, to meet the needs of zinc/aluminum/magnesium alloy die casting process, click on the consultation to get a free design plan!